Hindustan Pressings Private Limited – Sheet Metal Components Manufacturer

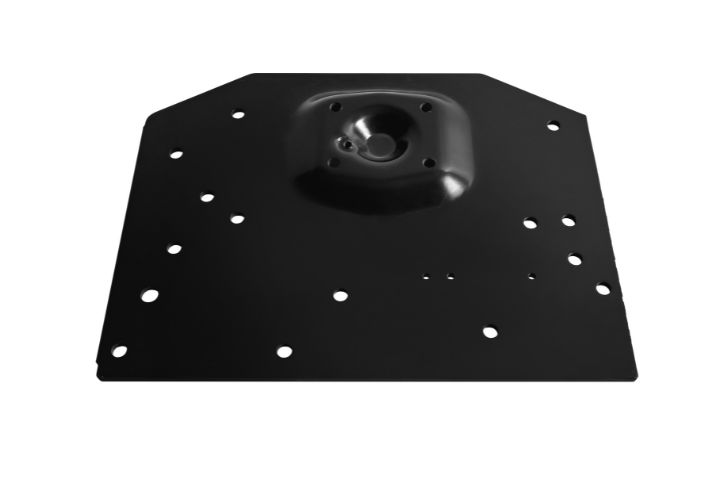

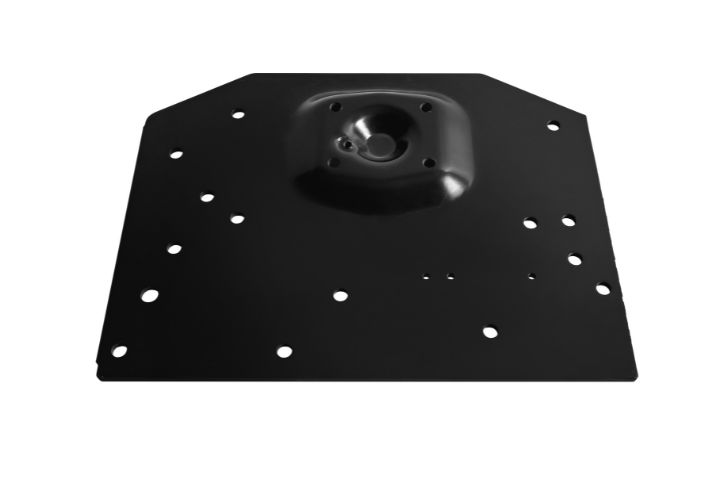

railways sheet metal components

Powering Railway Performance with Precision Sheet Metal Components

Overview

HPPL India stands out as a premier manufacturer in the realm of sheet metal components, dedicated to serving the specialized requirements of the railway industry. This company has carved a niche for itself through years of dedicated service and expertise, emerging as a frontrunner in the production of a wide array of sheet metal products. At the heart of HPPL India’s operations lies a commitment to leveraging cutting-edge manufacturing technologies, including advanced stamping/pressing, precision laser cutting, CNC bending, and proficient MIG/TIG welding techniques. This technological prowess is further enhanced by the company’s stringent quality control measures, exemplified by the utilization of Coordinate Measuring Machines (CMM) to ensure unparalleled accuracy and excellence in all its components.

HPPL India’s product portfolio is impressively diverse, encompassing everything from robust structural frames and supports, integral to the construction of railway carriages and engines, to the more intricate and aesthetically focused interior cabin elements. Each product is a testament to the company’s dedication to meeting the high standards of durability, safety, and performance that are non-negotiable in the railway sector. The company’s approach is not just about meeting the existing needs of the industry but is driven by a forward-thinking mindset, continually seeking innovative solutions and improvements in every aspect of their production process.

Client satisfaction is at the core of HPPL India’s ethos. The company prides itself on its ability to not just deliver products but to provide comprehensive solutions that align perfectly with the unique requirements of each client. This customer-centric approach, combined with an unwavering adherence to industry standards and ethical business practices, positions HPPL India as a reliable and esteemed partner for railway companies globally. In a nutshell, HPPL India is more than just a manufacturer; it’s a symbol of trust, quality, and innovation in the field of railway sheet metal component fabrication.

Railway sheet metal components

Get in Touch with HPPL !

Ready to enhance your operations with precision-engineered sheet metal components?

Our team at HPPL is here to provide tailored solutions to meet your industry’s needs.

Sectors / Industries

Durable Sheet Metal Components for Railway Equipment

At HPPL, we specialize in providing high-quality sheet metal components for the railway industry, ensuring the safety, durability, and efficiency of rail transport systems. From train chassis and carriages to braking systems and track components, every part we manufacture is engineered to meet the demanding standards of modern railways. With cutting-edge technology and expert craftsmanship, we deliver components that contribute to the reliability and performance of railway infrastructure.

Stamping is a manufacturing process used to shape metal sheets into specific designs through the application of pressure. The process involves placing a flat metal sheet, known as a blank, into a stamping press, where it is shaped by a die. The die and press work together to cut, bend, or form the metal into the desired shape, producing parts with precise dimensions. Stamping is commonly used in industries such as automotive, aerospace, and electronics to produce components like panels, brackets, and connectors, offering high-speed production and consistent quality for mass manufacturing.

HPPL’s stamping process is designed to produce durable, high-performance components for the railway industry. Using advanced lasers and presses, we manufacture essential parts like train chassis, track components, and carriages with unmatched precision. Our stamping ensures that every part meets the highest standards for strength, reliability, and functionality, essential for the safety and performance of rail transport systems.

CNC bending is crucial for creating the precise angles and shapes required in railway components. HPPL’s CNC systems provide high-accuracy, repeatable bends for parts such as train frames, structural supports, and custom brackets. Our technology ensures that every part is bent to exact specifications, guaranteeing a perfect fit and high strength in railway applications.

MIG and TIG welding techniques are essential for ensuring the durability and safety of railway components. MIG welding is used for thicker materials, providing fast and strong joints, while TIG welding offers superior precision for more intricate and thinner parts. These welding methods ensure robust, long-lasting welds necessary for components that endure the heavy demands of the railway environment.

Precision is critical in the railway industry, and our CMM ensures that every component meets strict dimensional and quality standards. Using advanced measurement technology, we inspect each part for precise dimensions, geometry, and alignment to ensure all components perform reliably within the larger railway system.

To meet the high-volume production needs of the railway industry, HPPL employs robotic welding technology, ensuring consistency, speed, and high-quality welds. Robotic welding is ideal for large-scale manufacturing of train chassis, tracks, and other structural components, ensuring durability and safety while increasing production efficiency.

Our tooling capabilities are designed to produce highly accurate components for the railway sector. With custom dies, molds, and fixtures, HPPL ensures that every part is shaped, cut, and assembled to exact specifications. Our tooling solutions enhance production efficiency and guarantee the quality of components like train frames, track components, and more.

Stamping is a manufacturing process used to shape metal sheets into specific designs through the application of pressure. The process involves placing a flat metal sheet, known as a blank, into a stamping press, where it is shaped by a die. The die and press work together to cut, bend, or form the metal into the desired shape, producing parts with precise dimensions. Stamping is commonly used in industries such as automotive, aerospace, and electronics to produce components like panels, brackets, and connectors, offering high-speed production and consistent quality for mass manufacturing.

Laser cutting is a precise manufacturing process that uses a high-powered laser beam to cut, shape, or engrave materials, typically metal sheets. The laser focuses intense light on a small area, heating and melting the material to create clean, accurate cuts with minimal waste. This process is controlled by a computer, allowing for complex designs and intricate details. Laser cutting is widely used in industries like automotive, aerospace, and electronics for producing components such as brackets, enclosures, and decorative parts. Its advantages include high precision, speed, and the ability to cut a variety of materials and thicknesses.

CNC bending is a manufacturing process that involves using a Computer Numerical Control (CNC) machine to bend metal sheets into specific angles and shapes. The process uses a press brake equipped with a CNC controller, which precisely positions the metal sheet and controls the bending force. By programming the CNC machine, complex bends and consistent, repeatable results can be achieved with high accuracy. CNC bending is commonly used in industries like automotive, aerospace, and construction to create parts such as brackets, enclosures, and structural components. Its advantages include precision, flexibility, and the ability to handle various materials and thicknesses.

MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) are two common welding processes used to join metals.

MIG welding involves feeding a continuous wire electrode through a welding gun, which melts and joins the metals. The process uses an inert gas, usually argon or a mix of gases, to protect the weld from contamination. MIG welding is known for its speed and ease of use, making it ideal for thicker materials and large-scale production.

TIG welding uses a non-consumable tungsten electrode to create the weld. The process also uses an inert gas, typically argon, for protection. TIG welding offers greater precision and control, making it suitable for thinner materials and applications requiring high-quality welds, such as in aerospace and automotive industries.

A Coordinate Measuring Machine (CMM) is a precision device used in manufacturing and engineering to measure the physical dimensions of objects with high accuracy. It uses a probe to detect the exact coordinates of points on the object’s surface, which can then be used to determine its geometry, dimensions, and alignment. CMMs can be manual or automated and are controlled through software that allows for detailed analysis and quality control. They are commonly used for inspecting complex parts in industries like aerospace, automotive, and tooling, ensuring that components meet precise specifications and tolerances.

Robotic welding is an automated welding process where robots are used to perform welding tasks. These robots are equipped with welding tools, such as MIG, TIG, or spot welders, and are programmed to execute precise, repetitive welds on a production line. The use of robotics in welding enhances productivity, consistency, and quality by reducing human error and increasing the speed of production. Robotic welding is particularly valuable in industries like automotive and heavy manufacturing, where large volumes of identical parts need to be welded with high precision. It also improves safety by keeping workers away from hazardous welding environments.

Tooling in the sheet metal industry refers to the specialized equipment and devices used to shape, cut, form, and assemble metal sheets into specific parts or products. This includes tools like dies, punches, molds, and fixtures that are designed for processes such as stamping, bending, punching, and welding. Proper tooling is essential for achieving precise dimensions, maintaining product quality, and ensuring efficient production. In the sheet metal industry, tooling must be carefully designed and maintained to handle the specific material properties and thicknesses, allowing for consistent and repeatable manufacturing of components in industries like automotive, aerospace, and electronics.

99%

Quality

Quality/accuracy accepted in the industry

99%

Capacity

Machine/Plant capacity considered in industry.

99%

Time Efficiency

How HPPL is more time efficient.

99%

Cost Efficiency

How HPPL is cost-efficient

Why Choose HPPL...

Driving Railway Excellence with Precision Manufacturing!

HPPL is a trusted partner in the railway industry, offering precision-engineered sheet metal components that enhance safety, reliability, and performance. With our state-of-the-art technology and expertise, we deliver components that meet the demanding requirements of rail transport systems. From the structural integrity of train chassis to the precision of track components, HPPL ensures your railway infrastructure operates smoothly and safely.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar .

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

Our Clients

On Track to Tomorrow: Trailblazers Revolutionizing the Rails