India's Leading

Sheet Metal Components and Fabricated Assembly Manufacturer

Hindustan Pressings Private Limited (HPPL) is a trusted name in the industry and a leading sheet metal components manufacturer in India, renowned for its exceptional quality, cutting-edge infrastructure, comprehensive in-house facilities, and competitive pricing.

Tonnage of steel used - 10,000 T / Year

No. of plants - 3

Press machine tonnage - 63 ~ 1000 T

QMS as per IATF 16949:2016

| ISO 9001:2015 | ISO 45001:2018 | ISO 14001:2015

Modes of transport - Road, Sea and Air

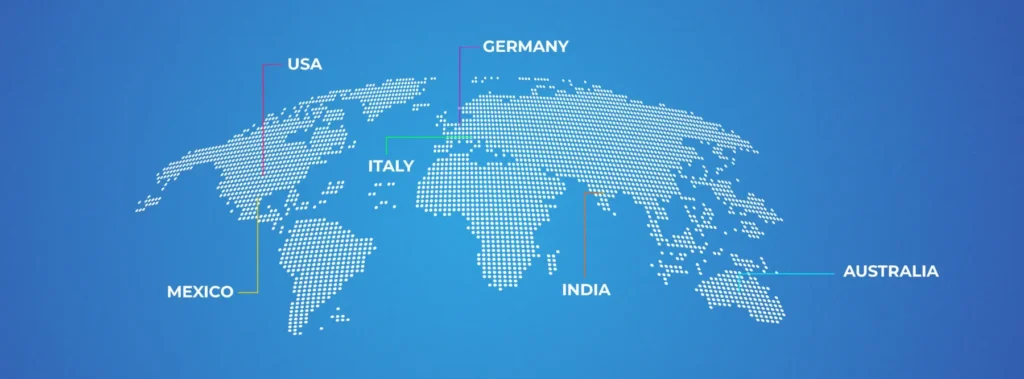

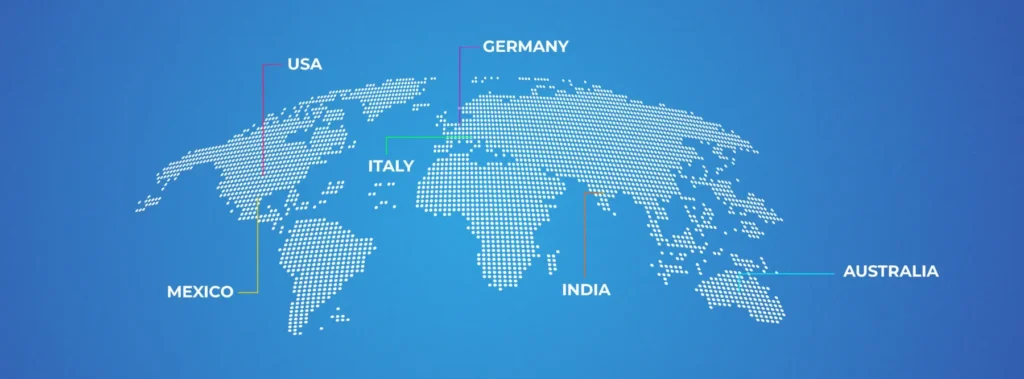

Countries we supply to - USA, Finland, Italy, Germany, Australia, India

India's Leading

Sheet Metal Components and Fabricated Assembly Manufacturer

Hindustan Pressings Private Limited (HPPL) is a trusted name in the industry and a leading sheet metal components manufacturer in India, renowned for its exceptional quality, cutting-edge infrastructure, comprehensive in-house facilities, and competitive pricing.

In-plant operations at Hindustan Pressings Private Limited

Tonnage of steel used - 10,000 T / Year

No. of plants - 3

Press machine tonnage - 63 ~ 1000 T

QMS as per IATF 16949:2016

| ISO 9001:2015 | ISO 45001:2018 | ISO 14001:2015

Modes of transport - Road, Sea and Air

Countries we supply to - USA, Finland, Italy, Germany, Australia, India

About Us

Hindustan Pressings Private Limited (HPPL) is a trusted name in the industry and a leading sheet metal components manufacturer in India, renowned for its exceptional quality, cutting-edge infrastructure, comprehensive in-house facilities, and competitive pricing.Founded in 1992, Hindustan Pressing Pvt. Ltd. (HPPL) is a trusted sheet metal components manufacturer in India, specializing in high-quality stamped and fabricated components. With over 30 years of industry experience, HPPL offers comprehensive in-house capabilities, including stamping and pressing (50 to 1000 tons), laser cutting, CNC bending, welding, machining, finishing, and advanced surface treatments.

Backed by three state-of-the-art manufacturing facilities in India, HPPL delivers sheet metal components that meet global quality standards. Our focus on innovation, durability, and process excellence enables us to serve diverse industries while consistently meeting domestic and international requirements.

Our Commitment to Excellence

Global Reach

Our product portfolio serves a wide range of industries in both domestic and international markets, making us a prominent sheet metal components manufacturer and exporter in India.

Years

Experience in exports

Containers

Exported till date

Tons

Shipped till date

Global Reach

Our product portfolio serves a wide range of industries in both domestic and international markets, making us a prominent sheet metal components manufacturer and exporter in India.

Years

Experience in exports

Containers

Exported till date

Tons

Shipped till date

Diverse Industrial Solutions for Different Sectors

HPPL delivers tailored solutions to various sectors, including Automotive, Agricultural, Material Handling, Elevators, Shipping, Solar and Railways.

To be a globally trusted partner in high-quality sheet metal components manufacturing, delivering precision-engineered components that exceed industry standards for performance, durability and sustainability while fostering innovation and long-term client partnerships.

To be a globally recognized leader in high-quality sheet metal components manufacturing from India , known for delivering high-performing, durable and cost-effective components while driving innovation, sustainability and operational excellence across industries.

Integrity, quality, innovation, customer commitment, sustainability and operational excellence. We ensure high manufacturing capacity, competitive pricing and on-time delivery while fostering reliability, ethical practices and continuous improvement.

Diverse Industrial Solutions for Different Sectors

HPPL delivers tailored solutions to various sectors, including Automotive, Agricultural, Material Handling, Elevators, Shipping, Solar and Railways.

To be a globally trusted partner in high-quality sheet metal components manufacturing, delivering precision-engineered components that exceed industry standards for performance, durability and sustainability while fostering innovation and long-term client partnerships.

To be a globally recognized leader in high-quality sheet metal components manufacturing from India , known for delivering high-performing, durable and cost-effective components while driving innovation, sustainability and operational excellence across industries.

Integrity, quality, innovation, customer commitment, sustainability and operational excellence. We ensure high manufacturing capacity, competitive pricing and on-time delivery while fostering reliability, ethical practices and continuous improvement.

Sustainability

At Hindustan Pressings Private Limited (HPPL), sustainability guides our everyday manufacturing practices. We are committed to protecting the environment, supporting our people, and building long-term value. As a trusted sheet metal components manufacturer in India, we work continuously to reduce our environmental impact and contribute to a greener future.

Building Future With Innovation

Stamping / Pressing

A wide range of presses from tonnage capacity of 50T - 1000T cater to large variety of parts required in more than 7 industries

Laser Cutting

With 3 laser and 2 fiber laser precision cutting machines, we ensure precise, complex cuts across different metal thicknesses.

CNC Bending

Our Bystronics & ISGAC-HACO CNC bending machines (110-400T) ensure high precision, handling lengths up to 6 meter.

MIG / TIG Welding

Our in-house team has mastered welding techniques, ensuring superior results for small to medium-sized parts.

CMM

Our CMM guarantee comprehensive quality control, ensuring consistent, high-quality components.

Tooling

HPPL’s expertise in designing and manufacturing tools ensures precision and reliability in every measurement.

Media

Our team is the backbone of HPPL’s success. Each member brings a unique set of skills, expertise, and a shared commitment to excellence. With a passion for innovation and a focus on customer satisfaction, our team collaborates seamlessly to deliver world-class solutions. Below, you can see the faces behind our achievements, driving HPPL forward every day.

Top Sheet Metal Components Manufacturer in India

Recognized by Industry Outlook magazine, Hindustan Pressings Private Limited (HPPL) stands as a Top Sheet Metal Components Manufacturer delivering reliable solutions across industries.

Quality | Safety | Sustainability

Working with

A Global Mission

Plant 1 & HO

Pressing / Stamping

QMS as per IATF 16949:2016

ISO 14001:2015 | ISO 45001:2018

Plant 2

Pressing / Stamping

QMS as per

IATF 16949:2016

Plant 3

Laser cutting | Bending | Pressing | Welding | Finishing

ISO 9001:2015 | ISO 14001:2015 | ISO 45001:2018