Our Infrastructure

We possess robust technical and administrative capabilities that enable us to consistently deliver high-quality products at competitive prices tailored to meet the diverse needs of our domestic and global clientele.

Our Strength

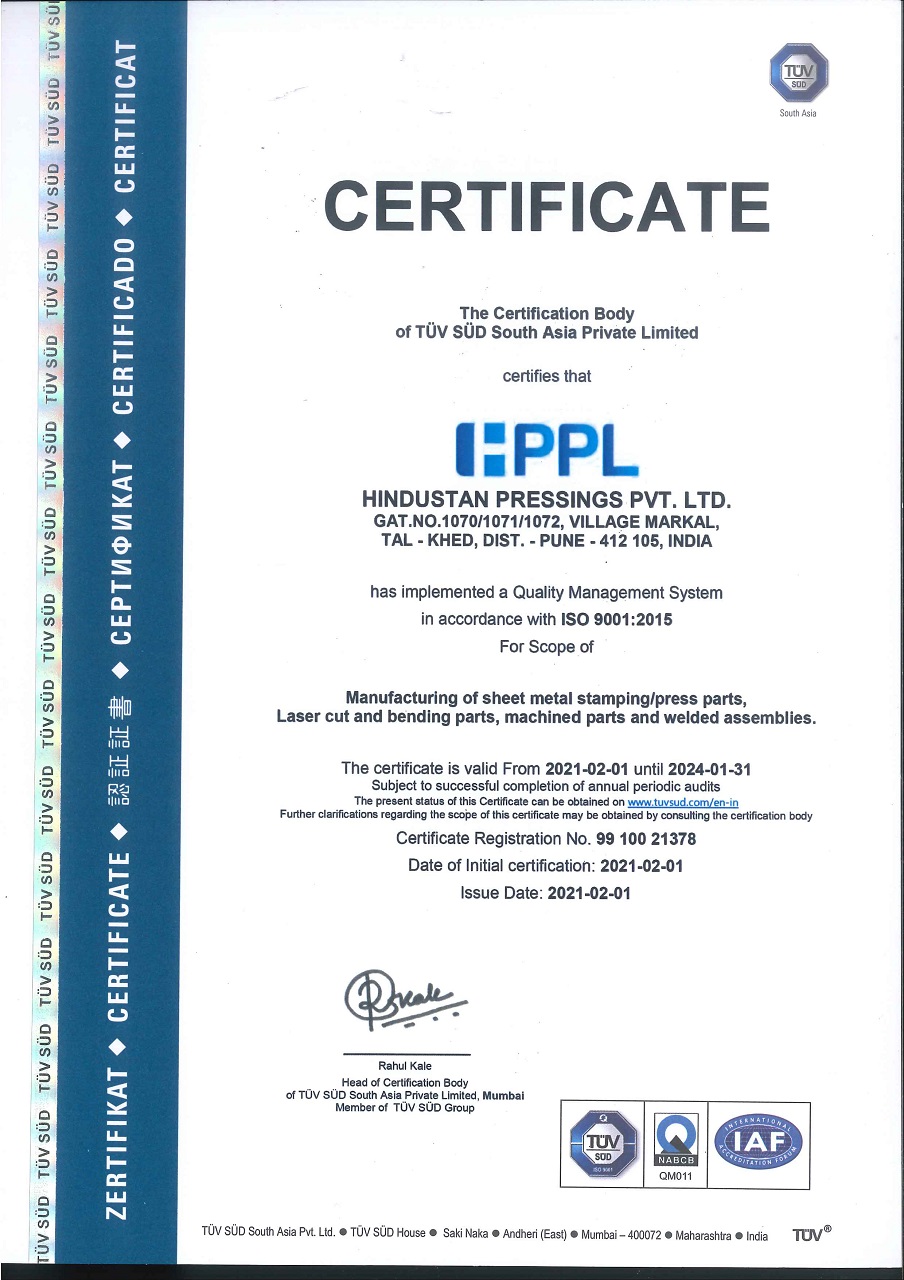

Committed to the relentless pursuit of excellence, HPPL consistently upholds the industry’s highest quality benchmarks while simultaneously prioritizing safety and environmental integrity. With over 60,000 square meters of land divided amongst 3 plants, we have immense scope of expansion to accommodate large projects. This steadfast dedication has earned us the esteemed accolades of ISO and IATF certifications.

Operations at HPPL

Quality Assurance

Quality Parameters

5 – S | APQP / PPAP | SPC / MSA | Calibration | PFMEA | ASTM Qualified Welder | DP & Destructive Test | Training

Material Grade

– CARBON STEEL CRCA IS 513 D / DD / EDD

– CARBON STEEL IS 1079 / ST 42 / ST 52

– Spring Steel C67 / C65 / C45 4. SS 304 / SS 316 / SS 409

– AL 6063 / AL 5052

Material Thickness

– 0.5 mm ~ 25 mm

CMM Details (Size)

X – 800 mm

Y – 1500 mm

Z – 600 mm

PROBE HEAD : PH10M PLUS (RENISHAW MADE)

5kw (2000 x 4000)

3D, Rotary axis & welding

Material Consumption

– 10,000 Tons / Year (Approx)

Team Of Experts

HPPL boasts a team of seasoned design and engineering specialists, whose unwavering dedication is to craft meticulous manufacturing processes and precision tooling for components and assemblies. These seasoned professionals employ cutting-edge technology to ensure optimal cost-efficiency and exceptional quality across any scale of production.

Our Manufacturing Units

Plant No 1 & HO

Pressing / Stamping (63 T~ 630 T)

- Phone:+1 (859) 254-6589

- Email:[email protected]

Plant 2

Pressing / Stamping (30 T~400 T)

QMS as per IATF 16949:2016

Plant 3

Laser cutting (3.0~5.0 KW) | CNC Bending (100 ~ 400 T) | MIG, TIG welding (manual & automatic) | Pressing (63 ~ 1000 T) | Finishing

ISO 9001:2015

Manufacturing Facility Highlights

HPPL is dedicated to achieving manufacturing excellence at a large and comprehensive scale. Our commitment to precision and quality is unwavering, making us a reliable choice for clients seeking excellence in manufacturing.

State of the art three units stretched across

Power presses ranging in size

63 T - 1000 T

Manufacturing parts and assemblies up to