Hindustan Pressings Private Limited – Sheet Metal Components Manufacturer

Our Infrastructure

We possess robust technical and administrative capabilities that enable us to consistently deliver high-quality products at competitive prices tailored to meet the diverse needs of our domestic and global clientele.

Our Strength

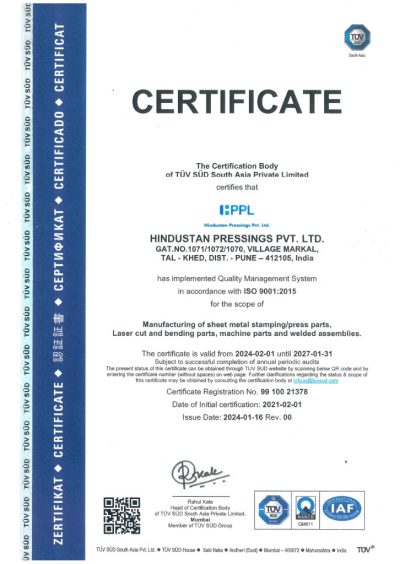

HPPL’s success stems from our unwavering commitment to excellence. We maintain the highest industry benchmarks for quality while prioritizing safety and environmental sustainability. With over 60,000 square meters of land spread across three cutting-edge plants, we are primed for future growth and large-scale projects. This relentless focus has earned us prestigious ISO and IATF certifications, a testament to our world-class capabilities. Our history of innovation and expertise further solidifies our position as an industry leader.

Building Future With Innovation

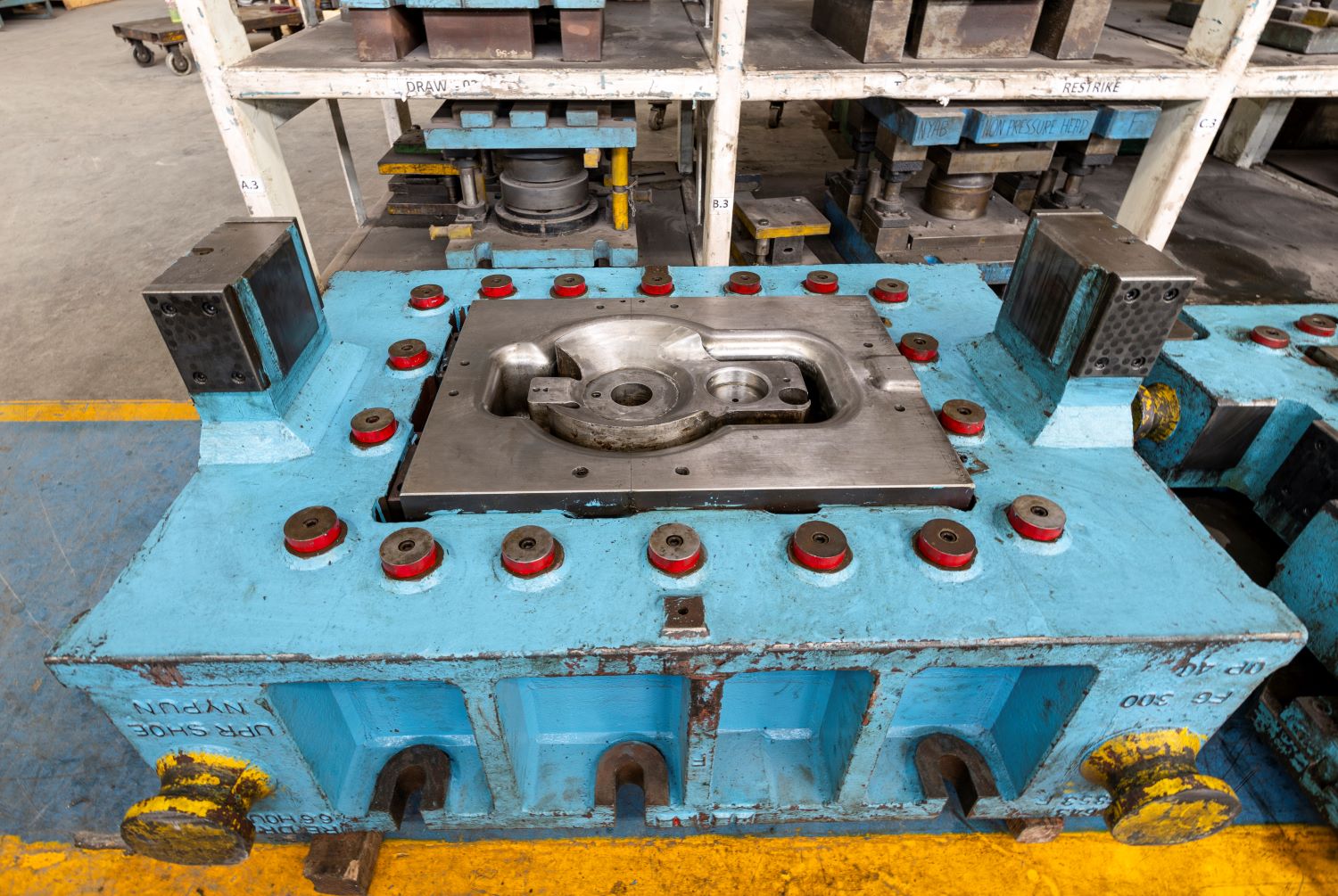

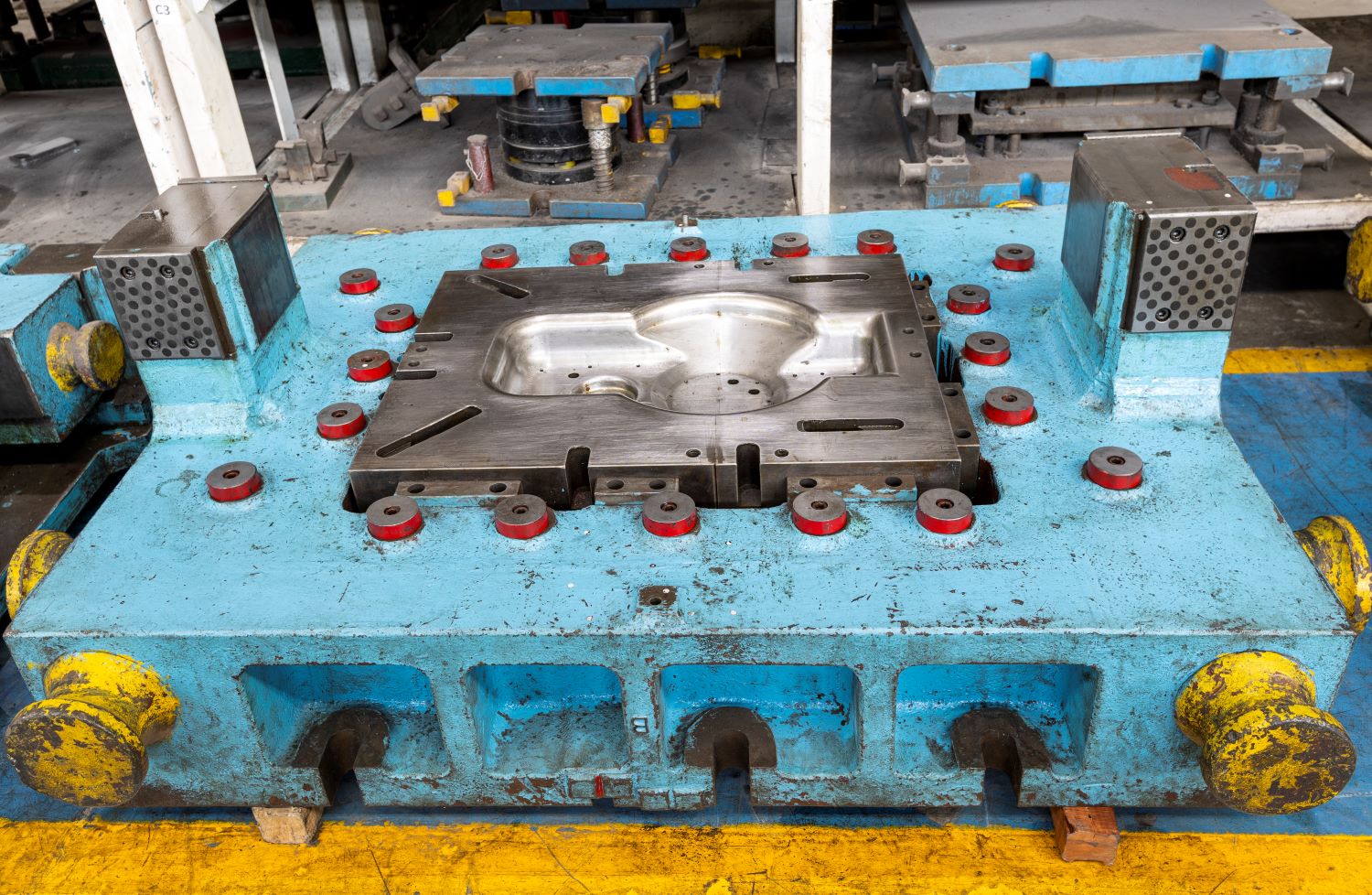

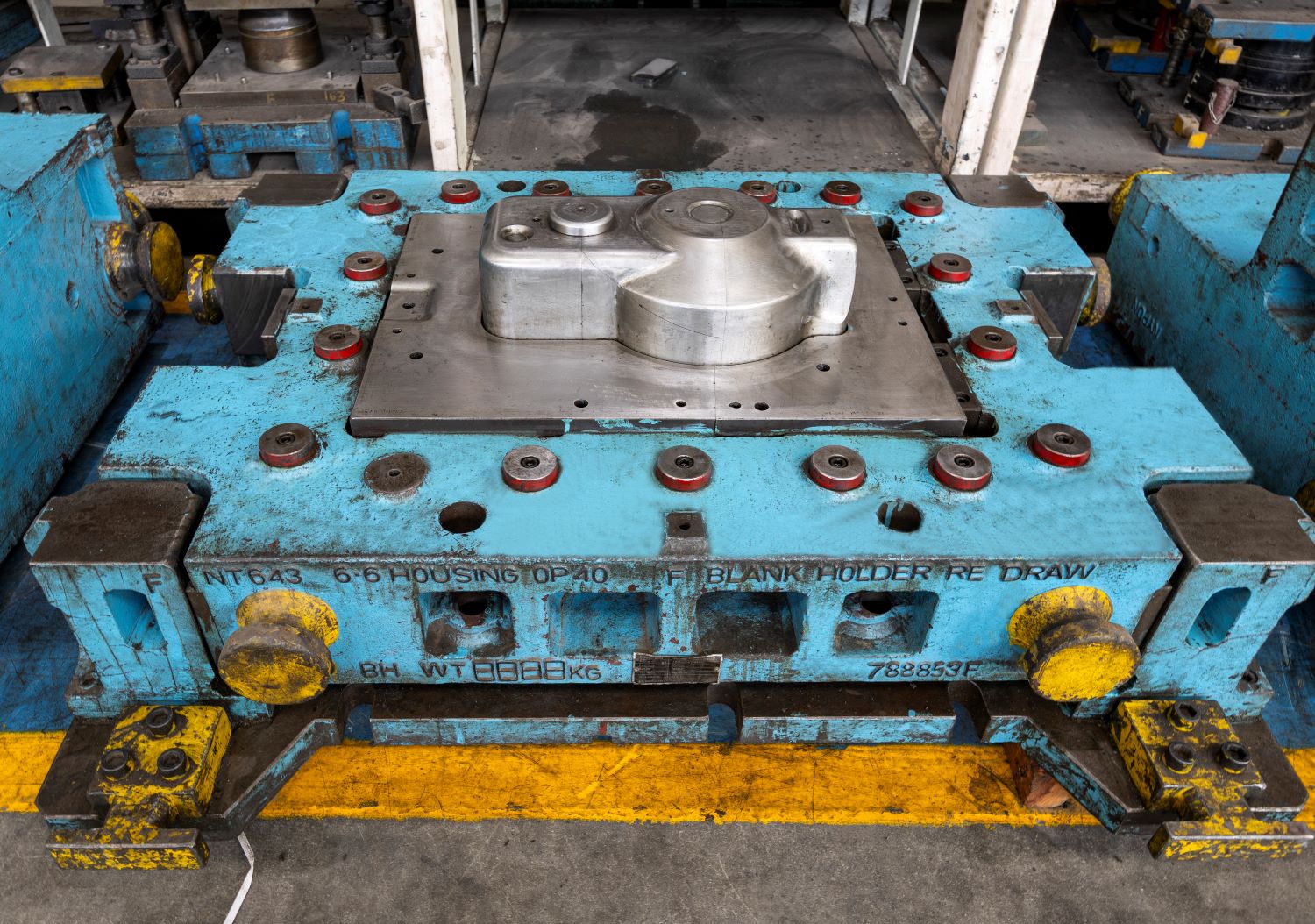

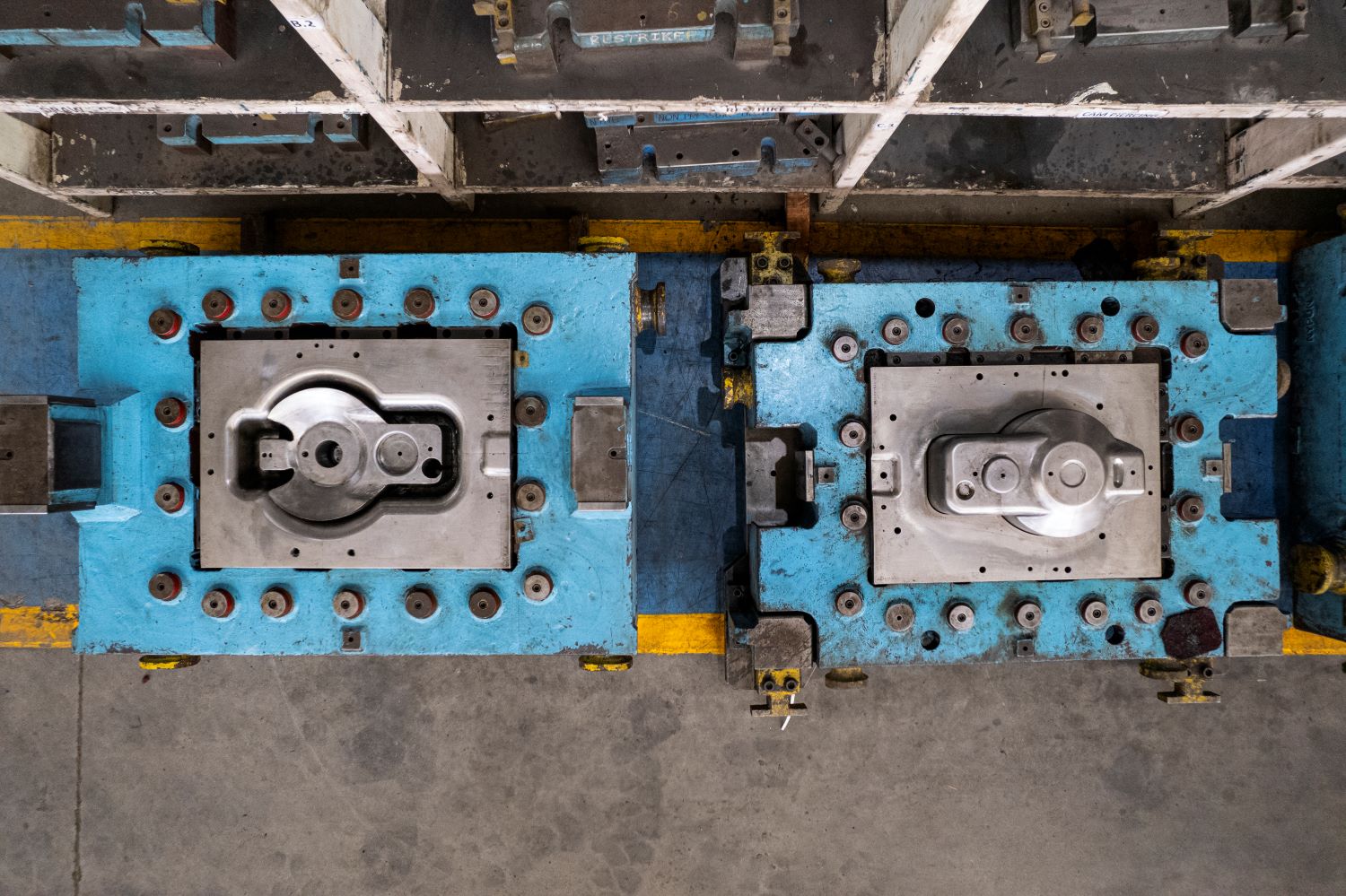

Stamping / Pressing

A wide range of presses from tonnage capacity of 50T - 1000T cater to large variety of parts required in more than 7 industries

Laser Cutting

With 3 laser and 2 fiber laser precision cutting machines, we ensure precise, complex cuts across different metal thicknesses.

CNC Bending

Our Bystronics & ISGAC-HACO CNC bending machines (110-400T) ensure high precision, handling lengths up to 6 meter.

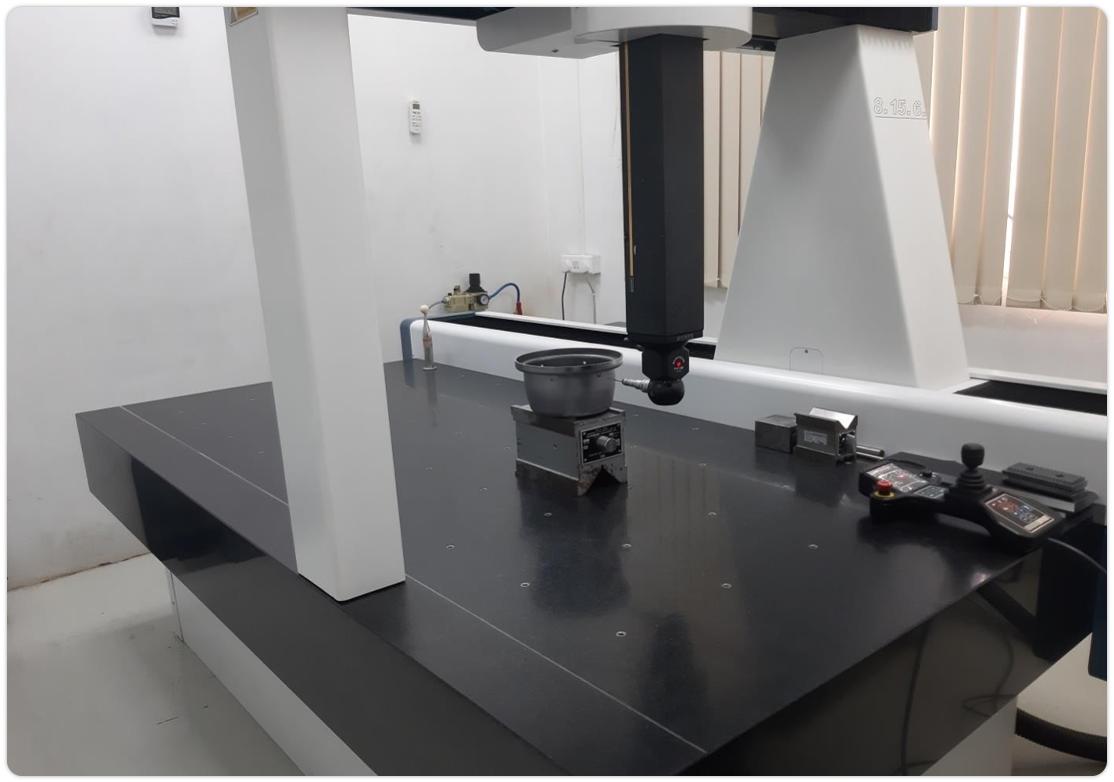

CMM

Our CMM guarantee comprehensive quality control, ensuring consistent, high-quality components.

Tooling

HPPL’s expertise in designing and manufacturing tools ensures precision and reliability in every measurement.

Quality Assurance

Quality Parameters

5 – S | APQP / PPAP | SPC / MSA | Calibration | PFMEA | ASTM Qualified Welder | DP & Destructive Test | Training

Material Grade

– CARBON STEEL CRCA IS 513 D / DD / EDD

– CARBON STEEL IS 1079 / ST 42 / ST 52

– Spring Steel C67 / C65 / C45 4. SS 304 / SS 316 / SS 409

– AL 6063 / AL 5052

Material Thickness

– 0.5 mm ~ 25 mm

CMM Details (Size)

X – 800 mm

Y – 1500 mm

Z – 600 mm

PROBE HEAD : PH10M PLUS (RENISHAW MADE)

5kw (2000 x 4000)

3D, Rotary axis & welding

Material Consumption

– 10,000 Tons / Year (Approx)

Team Of Experts

At HPPL, our greatest asset is our team of highly skilled design and engineering professionals. With years of industry experience and a deep understanding of manufacturing technologies, they create precise, efficient, and cost-effective tooling and processes. Their expertise ensures seamless scalability, making HPPL the trusted partner for both small and large manufacturing demands. The use history of our manufacturing excellence highlights our consistency in delivering quality and precision across every project.

Quality | Safety | Sustainability

Working with

A Global Mission

Plant 1 & HO

Pressing / Stamping

QMS as per IATF 16949:2016

ISO 14001:2015 | ISO 45001:2018

Plant 2

Pressing / Stamping

QMS as per IATF 16949:2016

Plant 3

Laser cutting | Bending | Pressing | Welding | Finishing

ISO 9001:2015 | ISO 14001:2015 | ISO 45001:2018

Manufacturing Facility Highlights

Our facilities are designed to achieve excellence at every step of the manufacturing journey. HPPL is equipped with advanced machinery, cutting-edge technologies, and streamlined workflows, ensuring:

- Precision-driven production processes

- Flexible capacity for large-scale projects

- Superior quality control mechanisms

- Environmentally conscious operations

With our rich history of success and dedication to progress, HPPL stands as a beacon of manufacturing excellence, ready to meet the evolving needs of our clients.

State of the art three units stretched across

Power presses ranging in size

63 T - 1000 T

Manufacturing parts and assemblies up to