Shipping sheet metal components

Powering Shipping Performance with Precision Sheet Metal Components

Shipping sheet metal components

Get in Touch with HPPL !

Ready to enhance your operations with precision-engineered sheet metal components?

Our team at HPPL is here to provide tailored solutions to meet your industry’s needs.

High-Performance Sheet Metal Components for the Shipping Industry

At HPPL, we specialize in manufacturing high-quality shipping sheet metal components, ensuring the safety, durability, and performance of vessels and maritime equipment. From hull components and deck structures to cargo handling systems and machinery parts, every piece we craft is engineered to meet the harsh conditions of the maritime environment. With advanced technology and expert craftsmanship, HPPL delivers components that enhance the reliability and longevity of shipping operations

Stamping is a manufacturing process used to shape metal sheets into specific designs through the application of pressure. The process involves placing a flat metal sheet, known as a blank, into a stamping press, where it is shaped by a die. The die and press work together to cut, bend, or form the metal into the desired shape, producing parts with precise dimensions. Stamping is commonly used in industries such as automotive, aerospace, and electronics to produce components like panels, brackets, and connectors, offering high-speed production and consistent quality for mass manufacturing.

Laser cutting technology at HPPL enables us to create precise, intricate cuts for shipping components. Whether it’s for structural elements, machinery parts, or decorative metalwork, our high-powered lasers provide superior accuracy with minimal material waste. This ensures clean, complex designs that meet the exacting specifications required for both functional and aesthetic applications in the shipping industry.

CNC bending is essential for shaping metal parts into the precise angles and forms needed for shipping equipment. HPPL’s CNC systems ensure high-accuracy, repeatable bends for parts such as hull reinforcements, decks, and custom brackets. Our technology guarantees that each component is shaped to exact specifications, contributing to the overall strength, stability, and safety of maritime systems.

MIG and TIG welding techniques are crucial for ensuring the durability and safety of shipping components. MIG welding is ideal for joining thicker materials quickly and effectively, while TIG welding provides the precision necessary for thinner, intricate parts. These welding methods are used to create strong, long-lasting joints that are essential for the harsh conditions experienced by maritime structures and equipment.

Precision is paramount in the shipping industry, and our CMM ensures that every part meets strict dimensional and quality standards. Using advanced measurement technology, we inspect each component for accurate dimensions, geometry, and alignment, ensuring that the parts fit seamlessly and perform reliably in shipping operations.

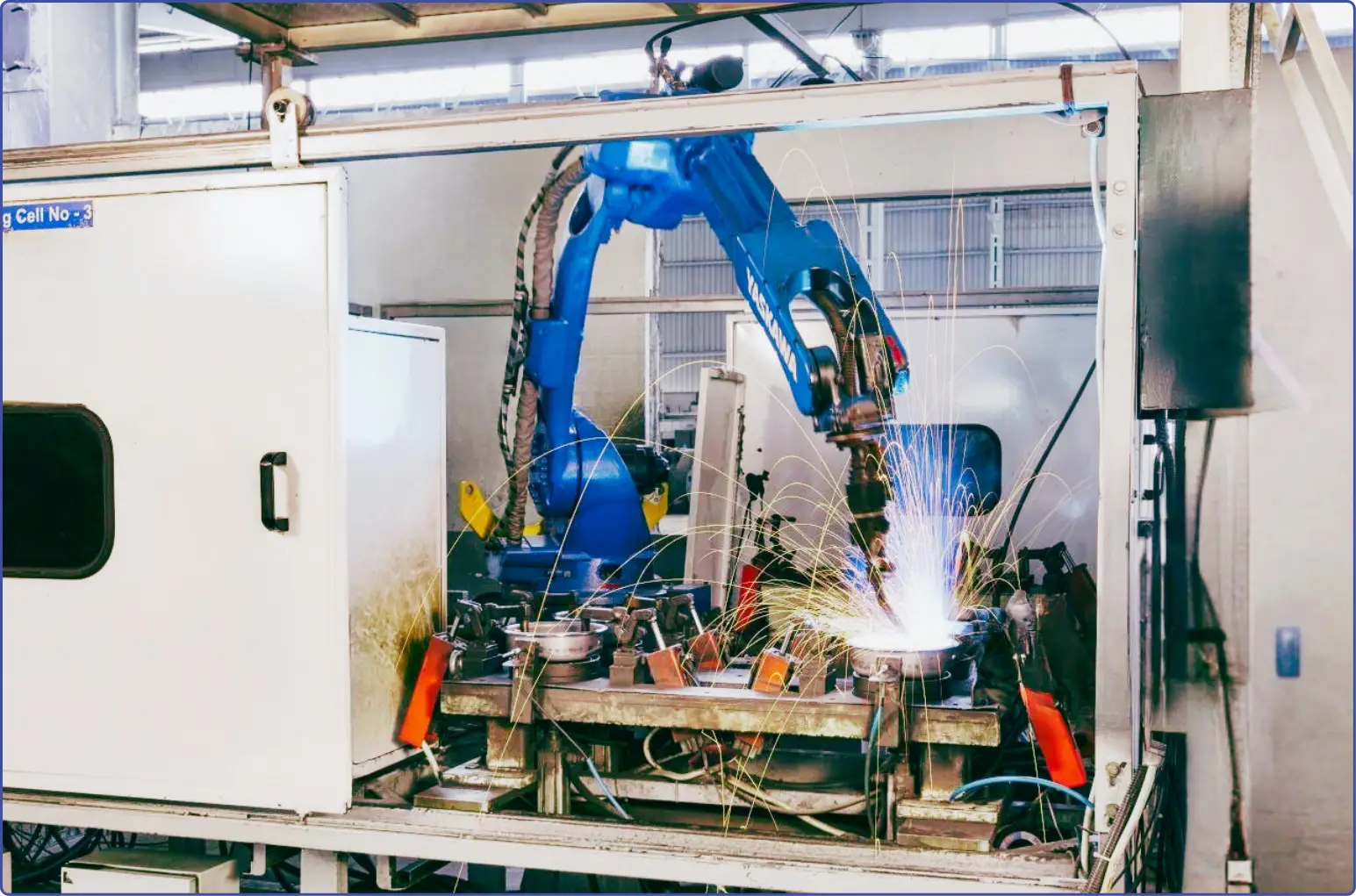

To meet the high-production demands of the shipping industry, HPPL employs robotic welding systems to ensure consistency, speed, and high-quality welds. Robotic welding is ideal for the large-scale manufacturing of structural components such as ship hulls, cargo handling systems, and other vital equipment, ensuring high durability while enhancing production efficiency.

HPPL’s tooling solutions are designed to produce highly accurate and durable components for the shipping sector. With custom dies, molds, and fixtures, we ensure that every part is shaped, cut, and assembled to precise specifications. Our tooling expertise guarantees that all shipping components meet the industry’s demanding standards for quality, performance, and reliability.

99%

Quality

Quality/accuracy accepted in the industry

99%

Capacity

Machine/Plant capacity considered in industry.

99%

Time Efficiency

How HPPL is more time efficient.

99%

Cost Efficiency

How HPPL is cost-efficient

Why Choose HPPL India...

Strengthening Shipping Operations with Precision and Durability!

HPPL is a trusted partner for the shipping industry, providing high-quality, precision-engineered sheet metal components that ensure safe, efficient, and reliable maritime operations. From structural integrity to functional performance, our components are designed to withstand the harshest maritime conditions, supporting the long-term success of shipping businesses. With advanced technology and unparalleled expertise, HPPL is committed to delivering the solutions you need for superior performance and durability.

Our Clients

Navigating New Horizons: Pioneers at the Helm of Maritime Innovation.