Agriculture Sheet Metal Fabrication

& Components Manufacturer

Powering Agriculture Performance with Precision Sheet Metal Components

Agriculture sheet metal components

Get in Touch with HPPL !

Ready to enhance your operations with precision-engineered sheet metal components?

Our team at HPPL is here to provide tailored solutions to meet your industry’s needs.

High-Quality Sheet Metal Fabrication and Components for Agriculture Equipment's

At HPPL, we combine cutting-edge technology with expert craftsmanship to produce precision sheet metal Fabrication & components for agricultural equipment. From robust frames to specialized parts, we deliver high-quality components that enhance the performance, durability, and efficiency of agricultural machinery. Every part we manufacture reflects our commitment to excellence, ensuring that farmers and operators can rely on equipment that meets the toughest demands of the field.

Stamping is a manufacturing process used to shape metal sheets into specific designs through the application of pressure. The process involves placing a flat metal sheet, known as a blank, into a stamping press, where it is shaped by a die. The die and press work together to cut, bend, or form the metal into the desired shape, producing parts with precise dimensions. Stamping is commonly used in industries such as automotive, aerospace, and electronics to produce components like panels, brackets, and connectors, offering high-speed production and consistent quality for mass manufacturing.

Laser cutting provides the ultimate precision in producing agricultural equipment components. With high-powered lasers, we can cut, shape, and engrave metal sheets with unmatched accuracy and minimal material waste. This technology allows us to produce intricate and complex designs for parts like brackets, enclosures, and structural elements—critical for the high demands of agriculture.

HPPL utilizes CNC bending to create parts with complex shapes and angles required in agricultural machinery. By programming our CNC systems, we achieve precise, repeatable bends that ensure the highest quality and performance. Whether it’s structural components or specialty parts, our CNC bending process guarantees accuracy and durability.

Our MIG and TIG welding capabilities ensure strong, precise welds for agricultural equipment. MIG welding is ideal for quickly joining thicker materials, while TIG welding offers greater control for finer work on thinner sheets. These welding methods are essential for producing durable, high-strength components that can withstand the demanding conditions of agriculture.

Quality control is critical in the agriculture industry, and our CMM ensures every component meets the required specifications. Using advanced measurement technology, we ensure that each part’s dimensions, geometry, and alignment are perfect, contributing to the reliability and longevity of the machinery it supports.

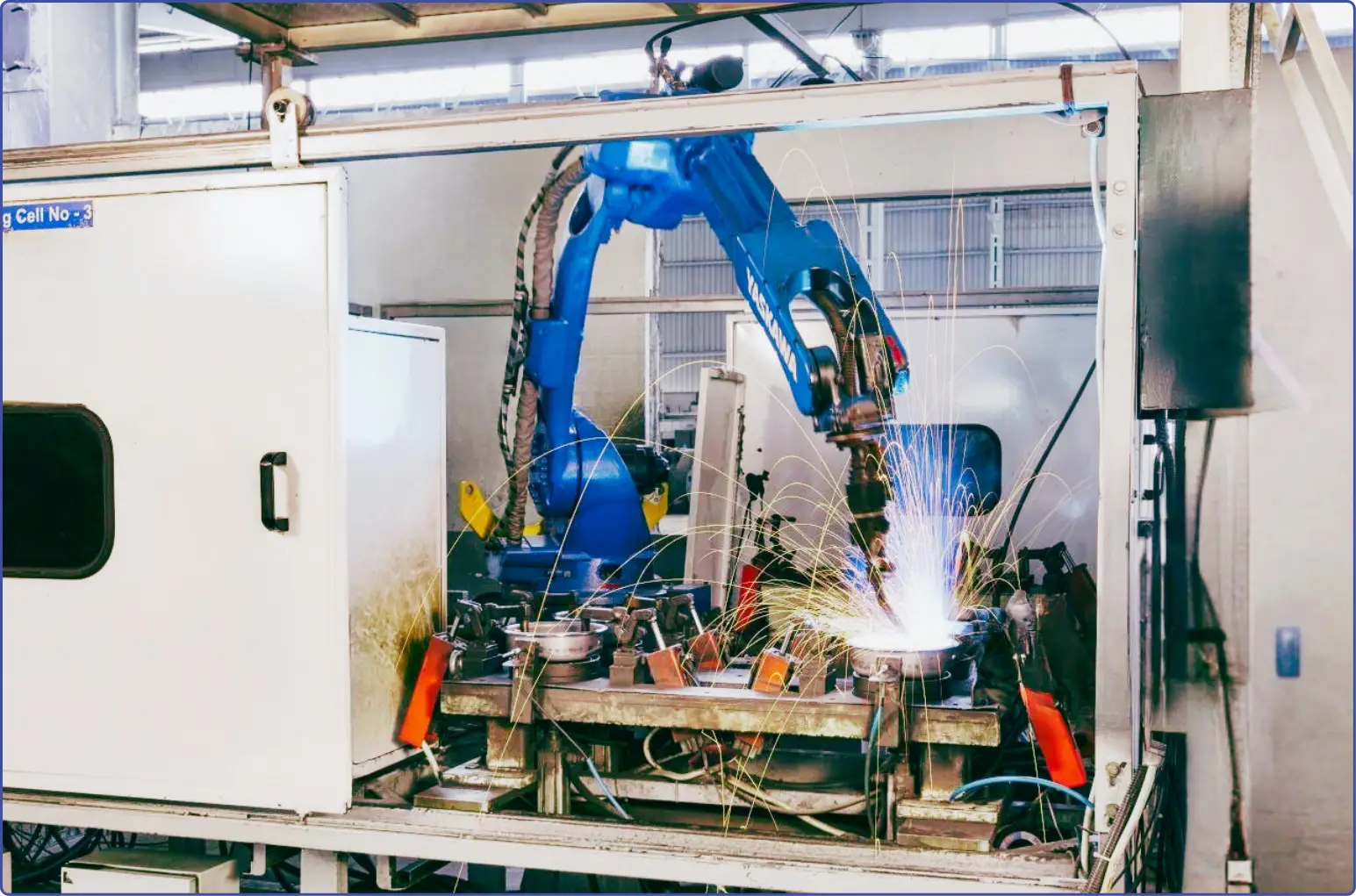

To meet the high-volume production needs of agricultural equipment, HPPL employs robotic welding for consistent, precise, and rapid welding. Our robotic systems increase production efficiency while ensuring top-quality welds, ideal for large-scale agricultural manufacturing where precision and durability are key.

At HPPL, our specialized tooling is designed to meet the unique requirements of agricultural equipment manufacturing. Using custom dies, molds, and fixtures, we ensure that each component is shaped, cut, and assembled to the highest standards. Our tooling expertise guarantees dimensional accuracy and efficiency in mass production, ensuring your equipment performs reliably and efficiently.

99%

Quality

Quality/accuracy accepted in the industry

99%

Capacity

Machine/Plant capacity considered in industry.

99%

Time Efficiency

How HPPL is more time efficient.

99%

Cost Efficiency

How HPPL is cost-efficient

Why Choose HPPL...

Driving Agricultural Excellence with Precision Manufacturing !

HPPL is your trusted partner for producing high-quality sheet metal fabrication & components for agricultural equipment. With a focus on precision, durability, and rapid turnaround, we help agricultural businesses meet the demanding requirements of modern farming. By leveraging advanced technologies and expertise, HPPL ensures the reliability and performance of every part, contributing to the success of your machinery and operations.

Cultivating Progress

Our Clients

Visionaries Redefining Agricultural Frontiers